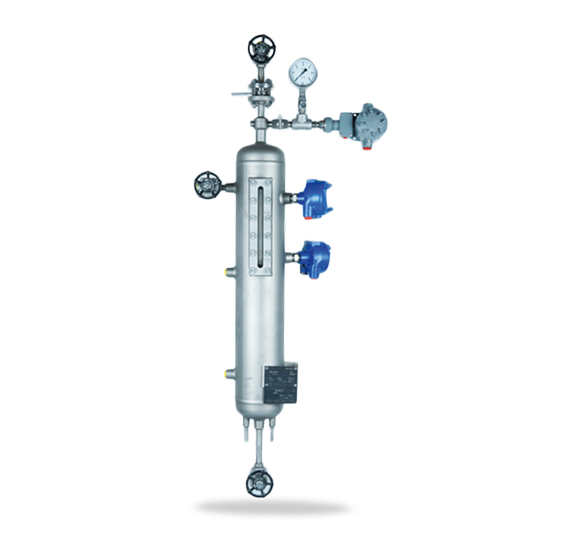

The TS system performs all the basic functions of a buffer/barrier system for the operation of double seals:

- to pressurize the buffer chamber

- leakage compensation

- buffer/barrier fluid is circulated by thermosiphon effects

- to cool the seal

- to selectively absorb product leakage and prevent dry running (tandem arrangement)

Use compressed air or nitrogen for pressurization; pressurization is monitored by a pressure switch. The incorporated level switch issues a signal whenever the level of buffer/barrier fluid is too low.