Home /

Our Products /

Seal Support System /

Thermosiphon systems /

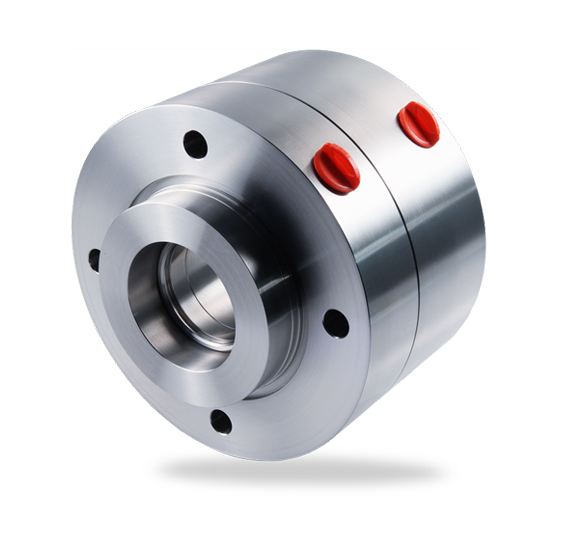

PS9DS

PS9DS

Features

- API 682 Category 2 and 3, Type A, Arrangement 3 seal

- Dual seal in face-to-face arrangement

- Same size of inboard and outboard seal

- Balanced

- Cartridge unit

- Stationary multiple springs

- Solid seal faces

Advantages

- Suitable for higher speeds

- Good followability due to no influence from run-out, squareness or vibration of the shaft

- Compact design

- Low heat generation and power consumption due to narrow seal face width

- Longer seal life

- Pressure-balanced design prevents mating ring being forced out under reverse pressure

- No damage to shaft sleeve as dynamic O-Ring is not in direct contact with the sleeve

Operating range

- Shaft diameter: d1 = 20 ... 110 mm (0.79" ... 4.33")

- Pressure: p = 60 bar (870 PSI)

- Temperature:t = -40 oC ... +176 oC (-40 oF ... +349 oF)

- Sliding velocity: vg = 50 m/s (164 ft/s)

Recommended applications

- Refining technology

- Oil and gas industry

- Petrochemical industry

- Chemical industry

- Power plant technology

- Light volatile hydrocarbons

- LPG plants

- API 610 / ISO 13709 pumps

- Process pumps

Materials

- Seal rings: Blister resistant carbon,

Silicon carbide SSiC (Q1), RBSiC (Q2)

- Mating rings:

Silicon carbide SSiC (Q1), RBSiC (Q2)

- Secondary seals:

FKM (V), FFKM (K), EPDM (E), NBR (P)

- Springs: Hastelloy® C-276 (M5)

- Metal parts: CrNiMo steel 316 (G), Duplex (G1)